About GHPs/HACCP

GHPs/HACCP is a systematic preventive approach to food safety and allergenic, chemical, and biological hazards in production processes that can cause the finished product to be unsafe, and design measurements to reduce these risks to a safe level. In this manner, GHPs/HACCP is referred as the prevention of hazards rather than finished product inspection. The GHPs/HACCP system can be used at all stages of a food chain, from food production and preparation processes including packaging, distribution, etc. These are guidelines to ensure that food remains contamination-free by making sure that all food operations are executed hygienically.

Benefits of HACCP

- You secure the trust of your customers.

- Focus on preventive actions helping to avoid unnecessary costs.

- You use your resources effectively to produce trustworthy food.

- The HACCP concept ensures compliance with legal regulations and reduces food safety risk, i.e., product liability risks, ensuring better food quality.

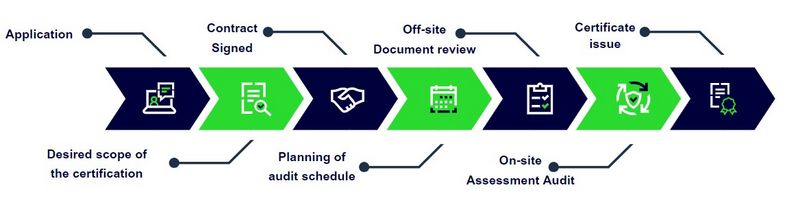

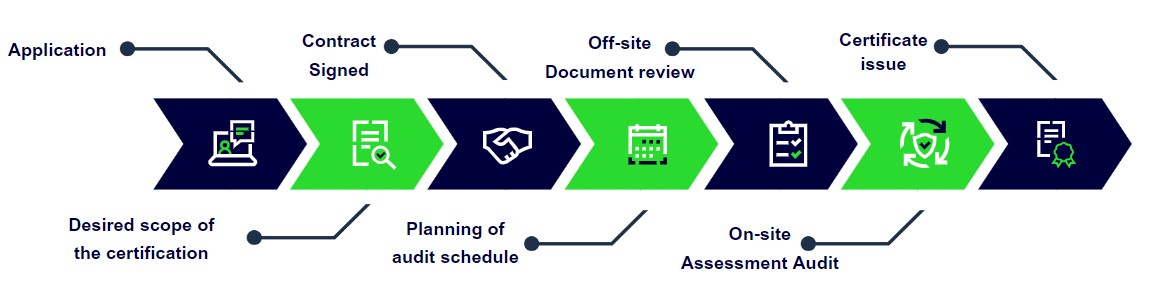

Certification Process

Why choose TÜV NORD

Our expert food industry auditors are specialists and are all approved for the GHPs/ HACCP standard. They identify strengths and weaknesses within your organization, discover potentials for improvement and structure all the tasks in the most efficient way possible. This means that we can accompany you securely and reliably along the fastest route to successful certification. Certification by TÜV NORD according to GHPs/ HACCP standards makes an important contribution to better food safety and therefore also in the end to sustainable business success